Spinny-Doo Spin Station Experiment - Metal Lens 4" Ø x 1000mm ROC

- Torin Walker

- Aug 11, 2018

- 5 min read

Product Idea

Occasionally, I get requests from customers to provide a suitable surface on which to spin a Spinny-Doo. In the past couple of years, spin stations have taken off with people using conventional convex lenses either alone or mounted in some sort of custom base, and the variety of these bases is becoming as varied as the top designs themselves.

The optimum configuration of spinning surface has several parameters both from a manufacturer's and a customer's standpoint including:

diameter

flat and/or concave

if concave, the radius of curvature (ROC),

glass type

cost

availability

Then there's the base itself in which this lens will sit. Material type, coloring, adjustment, angle indicator (e.g. bubble), adjustment screws (needed only if flat), and again, ease of manufacturing, and cost of final product.

While I could go nuts and engineer the base with all manner of exotic materials, indicators, adjustment screws, mounting locations for the Spinny-Doo, etc., I am more concerned with getting a spin-base to market, so the first design will be quite plain. I will provide a concave surface, quality glass, simple low-profile cup design, in a variety of colors, with felt bottom. Material will either be aluminum (easy to machine, but limited colors - at least in my area), or acrylic which comes in a wider variety of colors. Most of my effort is focused on the glass.

As for the surface, I initially dismissed lenses and looked for a more economical solution using borosilicate watch-glasses as they are very inexpensive and have a relatively tough and scratch-resistant surface. If I could keep the price very low, I could potentially offer a base to every single customer. Luckily, I happen to have found a few watch glasses I picked up decades ago during my regular visits to Active Surplus in Toronto. At the time, I thought the glasses were interesting and potentially useful in my varied experiments so I got a few and tucked them away in my oddities bin. These watch glasses are 125mm diameter with an aspheric curvature of ~300mm radius at the base, but increasing to more like 150~200mm toward the edges. It makes for a rather erratic settling of the top until it reaches center, then calms down. Also, too deep. I would prefer a shallower curve for a smoother, more relaxed spirographic pattern. These glasses were also cheaper - probably flint - and scratch very easily.

Before I considered (and finally rejected) watch glasses as a potential base, I was also looking at optical lenses, but initial searches turned up few candidates. I did not want to settle for a tiny base which I consider to be under 75mm, but as the diameter grows, so does the scarcity of the lens. Few manufacturer have regular stock lenses larger than 50mm, and of the ones that do, the focal distances tend to be much shorter than I prefer. I found a supplier of 100mm Ø x 300mm ROC, but they're shipping slow-boat-from-China (literally) and won't be here until October. Damn.

Not sure about 300mm, I thought I wanted something even larger - perhaps 500mm but couldn't find a supplier, so I started talking to lens manufacturers to have one made custom. I found one that can supply a plano-concave lens in borosilicate glass with dimensions of 100mm Ø x 500mm, but still couldn't visualize if the radius would be enough, so set out to prototype a lens on my lathe. For that, I would need to build a large radius tool.

Making a Prototype Lens

So without further ado, I would like to share my incredibly cheap but functional large-radius cutter. A design so frugal yet effective, I thought I needed to share it with you :-)

To start, I needed a pivot point to determine the vertex of the curve. I initially thought I would remove the tailstock and put some sort of fixture at the end of the lathe, but quickly realized I could use the tailstock itself - it's already dead on center, so I just needed to fashion a pivot using the MT4. With the taper tapped in, it should be able to hold. I had a couple of dead-ends, but made a taper on a piece of 1018 HR instead, then drilled and reamed for a very tight 1/4 dowel fit.

Next, I had some 3/4 square bar lying around. I thought of creating an adjustable sleeve using square tubing and drilling 10cm offset holes so I could vary the radius from 500mm to 1000mm, but overthinking as I often do would mean delaying the result. So, I just cut for one length.

Here is me precisely measuring for 1000mm ROC:

The radius ended up being 1030mm. I forgot to subtract the width of my thumb.

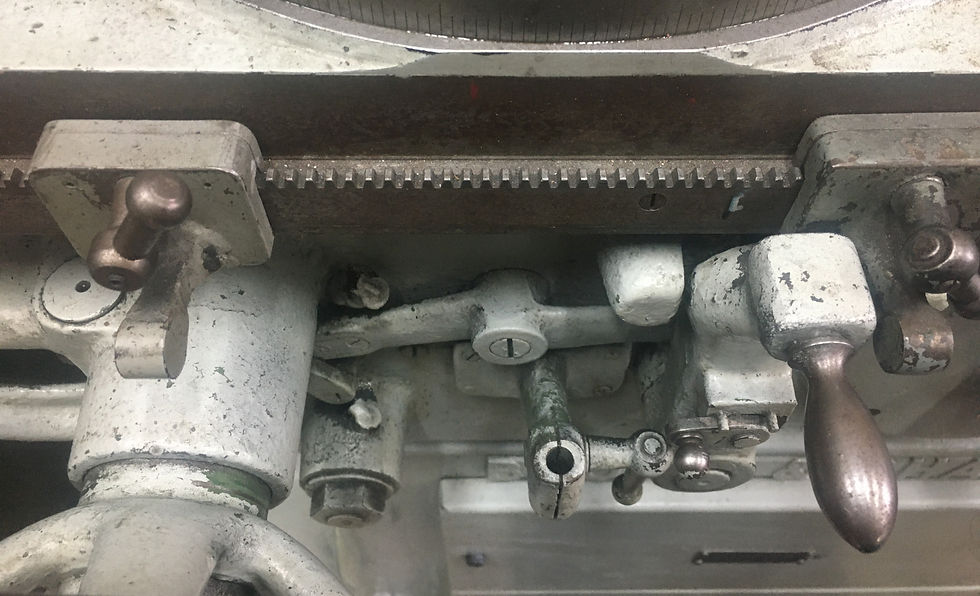

I initially thought I would create a shaft and use one the 30mm boring bar tool holders as a type of piston sleeve, then mount the bar at right angles with another pivot point and slot the bar for holding a tool, but then it dawned on me to loosen the toolpost slightly and use it as the pivot point instead. I secured the 3/4 bar in a 25-mm square bar toolholder with two screws and used the third to hold a round-nose HSS cutter on center with the bar. My lathe also allows me to disengage the handwheel so the carriage is free to slide, so this may not work with your lathe.

With the MT4 taper pivot fixed tightly in the tailstock, I could tighten the tailstock to fix the focal point. The cross-slide would then move the cutter into the workpiece while the carriage is free to float forward and backward as the arc progresses. It was brilliant. And cheap.

Here's a side view for further clarity (forgive the shaky panoramic)

Note: The radial cut moves along the X-axis, not up and down.

Once everything was tightened up, I took a couple of roughing cuts. This is the tool cutting a 1000mm radius into the workpiece:

And the result. The large radius on the cutter made the workpiece quite smooth to the touch, but not smooth enough.

I spent a bit of time sanding and polishing the surface to take the ridges out. I'm not trying to create a product here but rather a prototype a surface to see how the Spinny-Doo performs, which in this next video, seems to work nicely. If you notice the top hovering to the top-left from your perspective, it's because my desk is on a slant in that direction.

Finally, a short clip of the test result:

Conclusion

The 1000mm radius of curvature seems shallow enough. The Spinny-Doo doesn't whip around frantically as it does on higher-curvature lenses. I wish I could make an even larger radius to see how 2000mm performs. Perhaps if I take the tailstock off and bolt the pivot point to the concrete wall which is another 1m to the right...

For now, I'll wait until the 100mm Ø x 300mm lenses come in and give them a try, and of course, keep asking what customers want. I'll know then if I need to go beyond 1000mm or not.

Please comment if you have suggestions for what curvature you prefer.

Until next time, keep spinning.

Torin...

Comments