Restoring a B&S No. 13 Universal and Tool Grinder - Part 1

- Torin Walker

- Dec 17, 2020

- 3 min read

Updated: Jan 5, 2021

Having shut down the Spinny-Doo business and selling off the seldom-used Hardinge T42 CNC lathe, I wanted something in a cylindrical grinder for playing around. I already have a milling machine, a lathe, and a Boyar-Shultz H612 Surface grinder and this cylindrical grinder would be the complement to the surface grinder. I was also ready to break up with my Delta floor-model drill press; we had been going out for 20+ years, and with it being all wobbly and unrigid, it was time to move on.

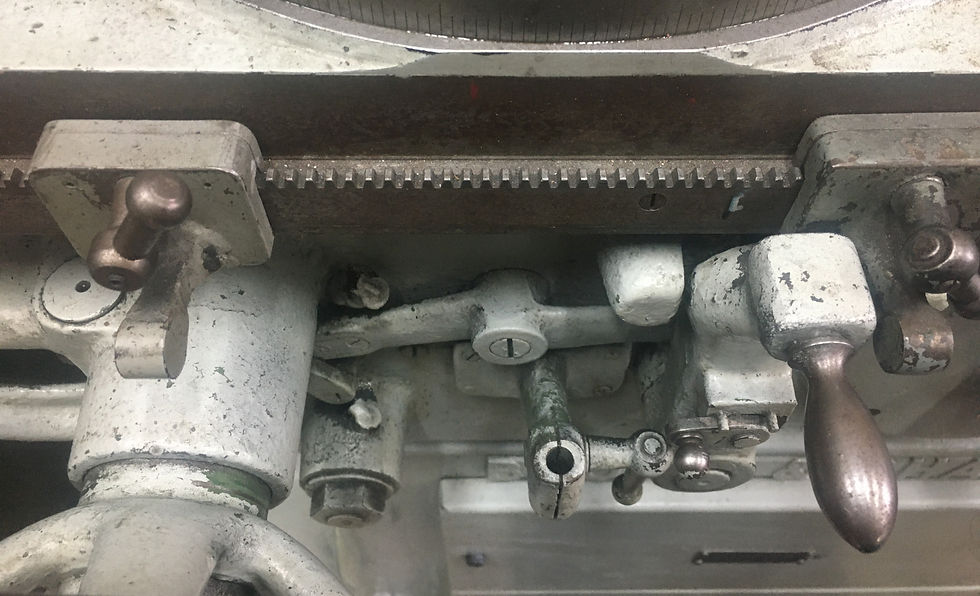

Introducing the Brown and Sharpe No. 13 Universal and Tool Grinder.

What an odd name... Universal and Tool Grinder.

Old wasn't my first choice, but given that it came with nearly every attachment ever made by Brown and Sharpe for this class of machine, I went ahead with it. Since then, I have gone from first-blush disappointment and buyer's remorse to reluctant acceptance and on to moderate contentment. The more I work on this machine, the more I am satisfied with the purchase.

Right off the bat, this machine is OLD. Like 1943, in the middle of WWII, no ANSI-standards old, with a U.S. War Department chalky, shitty whitewash paintjob caked in half a century of oil and grinding dirt.

Out of the crate, I see tags from the War Department and a placard on the front panel door that says (paraphrased) "We're at war, and this is the paintjob you get, so suck it -- WD." In another create, a lteral pile of attachments, bits and pieces. Some frozen, others not. Most useful, some not. Most haven't been used since the war and are hardened and stiff from oil turned to laquer. Each attachment was dismantled, washed in solvent, re-lubed, and reassembled. Good as new and smooth as silk.

It is my supposition that ANSI standards perhaps weren't as standard back then because, and perhaps I'm wrong, but fasteners and tapers back then were proprietary (tapers more than fasteners) and are now hard to come by. Fortunately, this technology is simple and mechanical and with adequate documentation (wait for it), fixing or replacing parts should be a simple matter of pulling them out and copying them with my other tools.

Restoring Attachments

The #13 came with a crate of attachments, including:

Angle Wheel Truing Attachment # 319

Centerstock # 5381

Cylindrical Grinder Motor-Driven Workhead Attachment # M1015

End Mill Grinding Attachment # 92

End Mill Grinding Attachment Tailstock # 3807

Firned Cutter Sharpening Attachment # 33

Index Center # 3807

Radius Dresser # 858

Radius Grinding Attachment # 1436

Tail Stock # 5381

Taper Holding Attachment # 206

Universal Head # ????

Wheel Guard # 1396

It came with many more attachments including other wheel guards, a wheel-guard mounting post, wet-grinding splash-guards and mounting posts, some custom v-notched plates the purpose of which I have not yet discerned, a number of overhead drive pulleys, some of the pulley and bearing blocks for the internal belt-spindle drive, and more. I'll post more pictures as I take them. If you know what any of these parts are or what they're used for, let me know and I'll make updates.

A few attachments will become useful right away, so I focused on these first:

A large 50-taper holding attachmen (#206) that spins on precision angled bearings - just need a 50-taper... something, probably collet chuck, in which to affix tools. This one was frozen from solidified oil and needed a complete dismantling and washing in gasoline.

A smaller 5-axis collet holder based on a B&S #9 taper, IIRC. This one I thought would be better suited for sharpening angles on items like chamfer mills, etc.

A radius grinding attachment (#1436) - this one was pretty smooth already and just needed grinding dust removed, and re-lube of the tapered gibs.

An angle-truing attachment (#319). It's a pretty big and complicated attachment for how little it does, but it just needed oil in the cups and a cosmetic cleanup.

The Universal Head - an interesting design which I'm sure will be extremely versatile once I get around to sharpening tools.

Minimum-Effort to Maintain

I don't have a history of this machine other than it came from J S Valve Company out of KY, USA and, I was told, this machine had been used as a surface grinder. Nothing more.

The main drive belt and pulley tensioning mechanism that drives the spindle through up through the hollow column is missing and replaced by a 1/2 motor seen at the top of the photo.

This blog is under construction. Further content/edits coming soon.

Comments