Radius Attachment for Do-All LD1340 Lathe

- Torin Walker

- Jul 17, 2017

- 7 min read

Updated: Jan 5, 2021

A little while ago, I made some BBQ skewers for a buddy and while rounding the ends, I used a combination of carriage and cross-slide feeds to turn the radiused end by eye. It got me thinking about radius cutters and radius attachments.

I spent some time looking at the wide variety of radius attachments out there, mocking up designs for each of the two major categories: those with a rotating base with t-slot guided toolholder and insert, and those that use a tuning-fork frame and swingarm (e.g. Holdridge Radii Cutter kits.)

The rotating base variety require fastening a baseplate to the cross slide, on top of which mounts a rotating platen with t-slot, then the toolholder itself. I figured I'd need no less than a 1/4 plate with countersunk flat-head socket screws, then at least a 5/8 ~ 3/4 plate for the t-slot platen. From the top of my cross-slide to the centerline is 3-7/8", so subtract from that the thickness of the base and platen plus some clearance, and at best I'd get around a 5" diameter sphere which isn't too shabby. However, since I have such a large clearance in front of the carriage, it seemed like a better idea to go for a tuning fork. The tuning fork would hang out in front and reach well below the cross-slide surface giving me a much larger clearance - possibly as much as 13" - the entire swing of the lathe. Even larger radii if I hold the tuning fork horizontally... but then I realized I was trying to boil the ocean and settled on a very respectable 6" diameter target.

Below is the initial design - a trio of swingarms allow for any diameter from 6" concave all the way to 6" convex. The largest swingarm is shown. The plate you see to the left with the notch cut out is where it would weld to the c-frame and this in turn would bolt to the cross-slide. It's too high in the drawing, so this is why in the upcoming pictures I only trim one side of the c-frame and leave a corner. You'll see what I'm talking about in a minute.

Once the design was settled, I bought a hondo worth of materials, the most expensive being the bronze (all prices in CAD, where 1 CAD = 0.76 USD)

3/4 x 6 x 12 Cold-Rolled - $25.00

3/4 x 3 x 9 Cold-Rolled - $11.00

3/4 x 1.5 x 9 Cold-Rolled - $6.00

1-1/8 diam C1018 (3 feet) - $17.00 (used 1/3, leaving extra for stock)

1" diam 660 Bearing Bronze - $35 (used about 1/3, leaving extra for stock)

2pcs M10 x 100 Grade 8.8 Hex Head bolts - $4.00

And an M42 1/4" 14-18 Bandsaw blade for contouring parts - $36.00

I spray-blued and scribed out the parts. This is all very rough. You can pretty much scribe out whatever you want, ignoring the drawings so long as you use the same circle dimensions. I used a 1.5" width section on the frame, and 1" sections for the swingarms even though the drawing calls for 1, 7/8, and 3/4 on the swingarms.

I installed the new 1/4 blade and started cutting. Cutting takes forever with a 14-18 TPI blade, but in only a few hours, all the parts were done. I contemplated milling the surfaces to clean up saw marks, but had enough clearance so I didn't fuss about the finish.

Check out the distortion after cutting only 75% through this plate. I put the c-frame and each swingarm in the mill and milled these flats parallel again before welding on the bushings.

The blade is just thick enough to separate the c-frame from the large swingarm to leave enough clearance that I don't have to relieve the back edge.

All parts are now complete and ready for assembly. Shown here is the corner (bottom right) left on the c-frame where the baseplate will be welded, which in turn will then mount directly to the t-slot guides on my cross-slide.

Cutting bushings for the pivot points of c-frame and swingarms. The thing on the right is a chip conveyor from my CNC lathe.

I get so focused on getting things done, I completely forget to show pictures of the setup. I'm such a forgetful blogger. To recap what I didn't take photos of: I place the C-frame on my table atop a pair of parallels that are exactly the same height as half the difference between the 3/4 plate and the 1-1/8 bushings. This lines up the bushings exactly centered on the c-frame/swingarms. I mill 0.125 down to create a ~3/4" wide flat on the bushing, clamp them in place and put two heavy tack-welds to keep it in place. I might mill them off and re-weld a straight bead, but for now, they're plenty strong.

Next, my design features bronze bearing sleeves - the original idea was to use socket-head shoulder bolts with the nice ground locating surface, but bloody hell.. it's Saturday and the local hardware stores never have what I need, so I opt for Grade 8.8 Metric M10 x 100 mm bolts and figure I'd be able to pop out the M10's in favour of proper shoulder bolts later if tolerance becomes an issue. In retrospect, I was probably overthinking this because the clearance of bushing/bearing to bolt is only 0.002", and they're round enough, so it is plenty accurate for whatever I'll be machining... like cannon balls, metal snow globes, and other not-terribly-accurate stuff (i.e. not optics). The proof will be in the pudding.

Bronze is both a pleasure to work with - machines kinda like tougher brass - and at the same time not so forgiving on drills. I break a crap chinese drill in the bore, but manage to fish it out and complete the part. I always use my crap chinese drills for roughing, then turn to my Precision Twist Drill set (or reamers) for finishing, and with this comes the risk of losing parts to a snapped drill. If ever you have a bit of spare cash, get yourself a 118-piece set of cheap drills and save your good drills for when you need accuracy and sharp cuts.

Here, I want to see how it will look and fit, and to see how thick the flange part of the bronze bushings need to be.

Man... just remembered I've got to water the stupid plants every few hours or they burn up in the sun.

So this is where the design changes: I decide I want the option of turning the frame perpendicular to the lathe axis. Plus, I have this QCTP holder with 40mm bore that has been staring me down ever since I bought it, so I fashion a spindle to fix the c-frame at its center point instead. This works out better as it makes mounting/unmounting the radius attachment MUCH faster than bolting it onto the cross-slide. I think I prefer it this way. Not as rigid, but far more convenient.

Finally, a use for that 40mm Multifix toolholder.

Using the QCTP holder as a collet block, I machine a 3/4 x 1" slot in the spindle.

And once again, I miss a bunch of welding photos. Just as well, I'm so out of practice, and I'm having trouble seeing what I'm doing as I get older. The welds are ugly, but I run it hot and get good penetration, so they're plenty strong. I should have TIG-welded them...

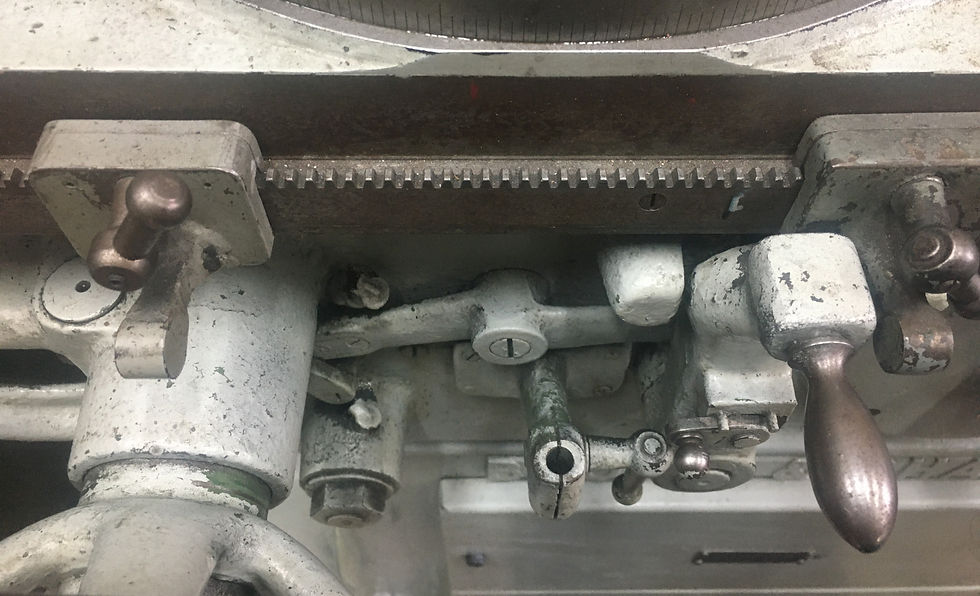

The C-Frame installed on the lathe - the largest swingarm gives me 7" capacity, which is 2" greater than a rotating base type radius attachment.

Smaller swingarms for smaller radii. I think I might make a simple cylinder with milled flat for very small concave and convex parts from the remaining 1-1/8 stock.

Setting up the large swingarm in the lathe

I trim the excess threads and get rid of the hex-heads (too hard on the fingers) in favour of knurled wheels.

Here's a shot of the small swingarm. Forgot to photograph that part of the build as well, but here it is installed.

And finally, I am eager to try it out, but this won't hold. Will need to wait until the tool holes are broached.

Each swingarm needs a 3/8" square bore for holding toolholders. Starting with the boring setup. Swingarms need to be brought up by .1875 so the top of 3/8 toolholder is on center with middle of the swingarm. Using calipers to offset (wrong shot - the proper offset is .1875)

Spot drill toolholder bore

Enlarge to 3/8" diameter

Same for medium swingarm

Spot-drilling large swingarm is a little more tricky as I have to drill lower to keep the 3/8 tool height at center.

At this point, I have a few options - I purchased some 3/8 sq O1 to fashion a square broach but instead try shaving the hole with a HSS bit held in my 4-jaw chuck, but the chuck was too big to get at the medium and large swingarms so I just file the holes square instead. I could have photographed all that, but you know what it takes to file a round hole square. No need to "bore" you with those shots. Also, sorry, forgot to show welding photos... not exactly equipped to take photos while both hands are welding :-) Afterward, I drill and tap two 1/4"-20 set-screws for each swingarm.

Set-screws installed

And now we can try it out. The moment I've been waiting for.

Trying out on a scrap piece of aluminum sitting around. Works fine enough, but need a better piece of scrap.

Trying it on some 1.5" 316L and it turns out beautifully, though my hands are dangerously close to the chuck while turning the swingarm by hand. A handle is planned, but just had to see how it worked.

Now using the yet-to-be-completed radius attachment to turn myself a finial for the swingarm handle.

I cut a piece of 1/2 Ø x 13" C1018 and turn 7/16" threads on each end. One end is turned down to .4375 for an additional 3/4 (-0.010) to fit through the swingarm. I then square and mill a block of steel to pinch the rod while I heat it with an MPS torch and bend the rod by hand to 90 degrees. Purely by accident, the rods bends in two locations giving it a subtle chamfer which looks cooler than a simple radius.

Swingarm handle completed and installed

Swingarm handle fits through a 7/16" hole, fastens with a knurled nut on the other side, and just clears the C-frame.

Finally, the project is complete. Now I just need a reason to break out the new hardware. If you're wondering why the medium swingwarm is upside-down, it's because I welded the #@%$ing set-screw tab on the wrong side of the swingarm. Sucks, but not important enough to repair it.

And, finally a closeup of the 316L turned sample.

Thanks for following along!

Torin...

Comments