On The Fence About Engraving

- Torin Walker

- Jul 9, 2018

- 2 min read

I've been thinking about engraving, laser marking, and pad printing for such a long time now, I've waffled on the idea. I originally mocked up a snazzy graphic of a Spinny-Doo with the curly SD logo and other essential text, then pursued numerous methods for imprinting, all to no avail. I apologized profusely to customers after failing to get YAG lasers operating (bought bad equipment), then again for failing to get PAD printing going (couldn't get the vendor to engage), and long contemplated the notion of engraving - rotating spindle engraving, and drag-scribe engraving - but then the lathe project, among other things, took precedence.

So why has it taken so long to get logos on Spinny-Doo? Well, the clean pristine surface of a Spinny-Doo, I think, is better than logos whirling by. Why mark it up with graphics and text when it looks so beautiful just standing there, rotating, and slightly shimmering? Graphics would destroy the illusion of the top standing perfectly motionless while turning. So marking the upper surfaces, at least, are out. Perhaps I might mark the bottom only if I can keep it faint and neat.

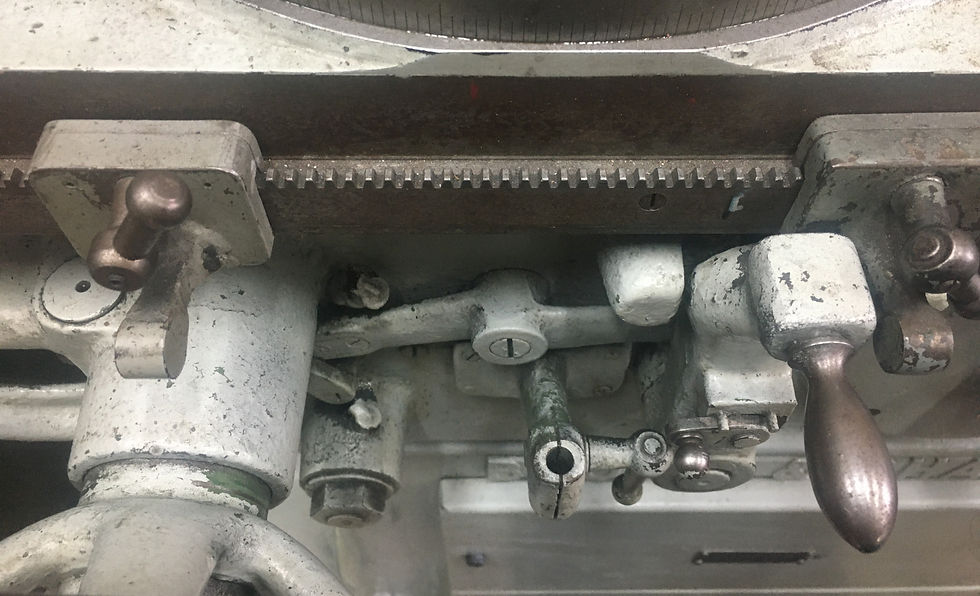

Having a bit of free time on my hands now that the lathe project is out of the way, I thought I'd take a stab at finally, FINALLY putting a logo to the Spinny-Doo.

Cobbling together a bit of vector graphics, I work out the kinks between what my SVG program produces and what the CAM program expects - translation issues between the required a bit of cleanup after importing into CAD

Next, turn the vector output into CAM (machine tool paths)

Experiment Result

Unfortunately, I don't have the proper spindle speed (max 4000 rpm. Should be 30,000 to 50,000 rpm), nor do I have the proper tool bit which happened to be whatever I found in the end-mill bucket that was fine enough, would clear the crown, and reach down to the plateau.

This bit had a sharp point and two flutes, but was nearly .015 across at the finest point making more of a bull-dozer than a fine-tipped surgical instrument. Still, it was fun to see how much I could get done in just a couple of hours. I excitedly offered to engrave stuff for my kids as I showed them the results. They said, "whatever."

The astute observer will notice two things - there is an 'n' missing in the far-side "Made in Canada", and the rim engraving needs to be scaled 1.012 x larger so the dots in the 'i''s don't fall off the inner edge. Third and probably not obvious is that I the depth of cut is slightly deeper on one side due to the shoddy ad-hoc spacer I had under the body.

What you see above through a x10 loupe is the result of aluminum being pushed around by the big fat tip of the tool instead of being carved away. This is normal and again, expected, for what I cobbled together from scrap tooling.

The proper method will be to obtain a spring-loaded diamond-tipped drag engraver and fine-tune the results by playing with font, line thickness, spring pressure, etc.

Time to shop for a suitable drag engraver that will clear that crown.

Until next time, keep spinning.

Torin...

Comments