Milling 20-sided Dice Using Fusion 360 and a 5-axis Mill (3+2) (part 1)

- Torin Walker

- Mar 27, 2019

- 8 min read

It's Really 3+2 Axis Machining

I know I'm going to get in trouble using the term 5-axis here because it's really 3+2 (positional) machining, but I had to attract people who might be looking for 3+2 machining by the wrong keyword.

Technically, one is "5-axis machining" when all 5 axes are fully-coordinated and moving simultaneously. A perfect example of this is milling the complex, compound curves of a turbine impeller; all five axes are turning in concert to ensure the ball mill maintains a specific angle of a attack normal to the part surface.

Positional (3+2) milling on the other hand is when you orient the A/C or B/C axes to a particular angle then use conventional 3-axis milling to perform an operation. The distinct advantage of 3+2 milling over conventional milling is the angles are programmed and the angles changed by the program, not the operator.

By the way, 3+2 isn't just limited to 90-degrees as illustrated above. In this example, I use 3+2 milling at a number of odd angles to create custom D20 (polyhedral) dice for a recently rediscovered interest in D&D. I make a few for my son, my brother (who came up with the idea and gave me a set of his own jumbo dice), and at least one for myself. As an added bonus, nothing gets you on your wife's better side than hundreds of little dents in the dining room table from massive metal dice, am I right?

Onward

There's nothing special about these dice, really, that would justify spending all this time and effort. It started during the Christmas holidays. A neighbour mentioned wanting to play D&D, plus I had a brother who I recall being a decent DM, and it had been decades since I played. When my brother came over, after the game he showed us some enormous plastic dice stating that while not practical, there is a demand for novelty dice.

Original, normal sized polyhedral dice

Large or "jumbo" polyhedral dice (my preference)

And then there's "novelty" dice (guy above is not my brother, though that is the size of die he had on hand.) And of course, we wouldn't be us if a few nerds didn't take it too far:

Ok, moving on.

While I tumbled my newly gifted set of bright yellow jumbo dice, I suggested it would be interesting to machine my own "jumbo" polyhedral dice perhaps in aluminum or brass, starting with the D20. Over the remaining Christmas holidays, I set to task and delved into 5-axis machining using Fusion 360. The benefit, perhaps less about making novelty dice, and more about finally putting to use my Nikken 5AX-120 table in a full 5-axis-enabled machining configuration.

Parametric Models vs Scalable Models

I started with the most-used die in the D&D polyhedral set: The 20-sided dodecahedron. I designed it initially using a parametric model where I could change one parameter - the length of the side of a triangle - and cause the whole die to scale, as well as choose from different fonts which also would change size along with, except I couldn't get the font to center within the face as the die changed size due to a Fusion limitation in how the fonts are referenced. Long story short, I decided instead to permanently fix the fonts and scale the whole model instead. Problem solved.

I'm greatly simplifying the steps here... truth be told, I had to go back and forth I don't know how many times to fix missing edges, deleted references, missing faces, mis-oriented fonts, etc. I had to recreate the model several times from scratch to catch and fix mistakes and learn as I developed the solution. Eventually, a fixed model that is scaled after the fact just made things easier.

My "D20-J28-OE" model (D20 for the number of sides, obviously, J28 for jumbo 28mm, and OE for the Old English font.)

Out-of-the-Box CAM Operations

Next, I set up the CAM path (now renamed "Manufacture") to mill the flats, engrave the fonts, flip the die over, and repeat for the other side. By selecting an operation and a face, Fusion wants to mill everything with the end of the endmill which I don't like. It's great for engraving the fonts on each face, but not for creating smooth clean face cuts. I wanted to finesse the operations to perform side milling for a nice smooth single-pass cut on each face. To do this, one must first select the face and create a plane perpendicular to the face to be cut, then select that plane and create a sketch outlining the path of the cutter extending from one side to the other, with extra distance on either side to accommodate lead-in as well as the radius of the cutter.

Some faces only require a boundary to be set. Others, such as face 18 shown here with its compound angle require that a reference plane be created first, then a sketch or "machining boundary" as I've called it.

Step 1: Pick a face and using that face, create a sketch. In that sketch, draw a line. This line will be the pivot reference for a reference plane to be created next.

Step 2: Create a reference plane using the sketch line just drawn and an offset angle. In this case, my angle is slightly over 35 degrees from the Z axis.

Step 3: Create sketch with boundary for the cutter. In my case, I wanted the cutter to be be confined within the boundary, so I had to make the area large enough to accommodate the lead-in and lead out of the cutter, as well as its radius.

Another view of the boundary. The cutter if imagined would be vertical and performing side-milling of face 18.

Step 4: Select path for operation using previously sketched bounday. You will also need to configure the orientation of your tool so that X is normal to the face, and Y and Z are parallel with the face. You can use the face and straight edge of the machining boundary to define your X and Y. Z will fall in accordingly.

The finished toolpath, now using the side of the milling cutter instead of the end, I take a few roughing passes, followed by a finishing pass that cuts the face using the entire length of the cutter.

Table Offset Machine Configuration Param Not implemented

Once I figured out the CAM paths and was satisfied with the cuts, I generated a program and reviewed the axes movements to see if they were within the very small cutting envelope of my Mill and Nikken TR table. I noticed that the Z and X axes did not move within the approximate 4-inch range I expected, so something was wrong. The machine was ignoring the B-axis offset I had configured in the setup.

Upon investigating the machine configuration for 5-axis, I learned through the Fusion's CAM Engine documentation that the B-axis offset parameter is actually not implemented. This explained why when I re-oriented the part for each new cut that the X and Z axes only moved a small amount. It was because I had set the origin to the top-center of my collet, and it was only moving the model the distance required to orient the part relative to that offset when I actually needed it to orient the part using the center of the B-axis.

At this point I had to stop and work backward to reestablish the proper machine setup, including table axis, table platen, whatever fixtures I was using, the stock, and placement of the model. Because this offset parameter isn't implemented, one must set the origin at the intersection of the B and C axes of rotation. In my case, the B axis is 75mm below the C-axis table surface, then the part sits in either a chuck or collet above that.

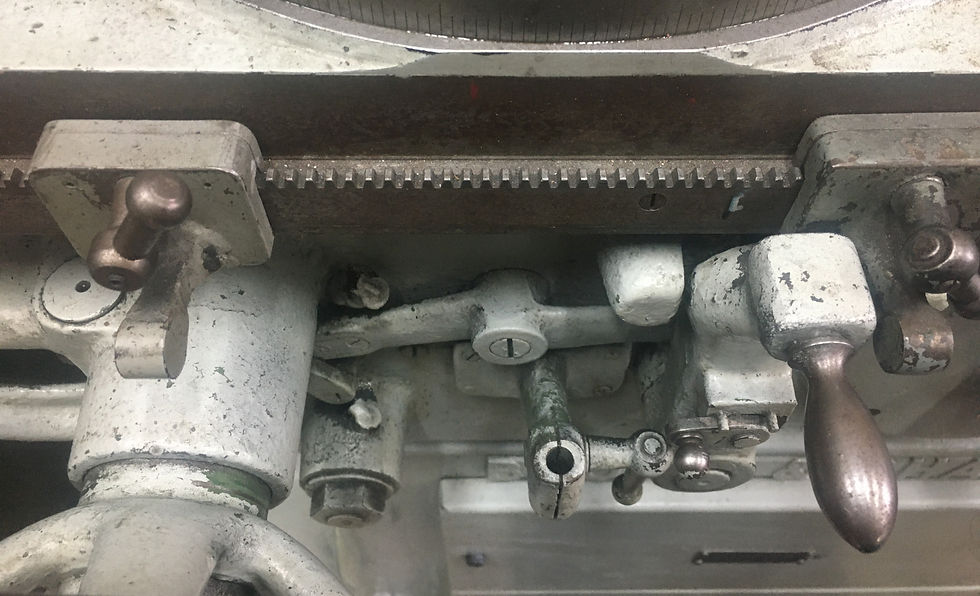

For this, I had to go and measure and model everything.

I actually prefer to see the environment in which the part is being machined, whether it's a Kurt vise, or a three-jaw, or a collet, and the fixtures on which they mount. In my case, for this project, I modeled my 5AX-120 table, then the AEG low-profile 4-jaw chuck I use for workholding. When I realized the chuck wouldn't hold the second half of the die. I turned a couple of solid 5C emergency collets on the lathe. For the first, I bore a pocket 1.25 diam x 0.5 deep and split the collet with by bandsaw (what a mess.) For the second, I took the die model and subtracted it from the 5C collet leaving an impression of the die where four vertical faces could be used to hold the die while being machined.

pictures

It actually helps to design a fixture containing the table first, then model your chuck and/or 5C collet, then save this as a fixture model. Then you go into the model of whatever you want to machine, import the fixture, and move the fixture relative to the part you're machining. Remember at this point you're setting the origin to the origin of the 5-axis table, not to your model.

My fixture has the table anchored, with tilting table, rotating table, a 4-jaw chuck, and 5C collet. I simply turn off whatever fixture I am not using and move stuff around relative to the stuff I am using.

I'm more practical than thorough. I needed to model my table, so I did the minimum necessary. Some guys will go into painstaking detail to include every little edge, crevice, screw, vernier, etc., right down to the color. I just wanted to get it done.

My 5AX-120 table model with joints for B and C axis, to exacting measurements, but not exacting cosmetic detail.

Once the model was complete, I made it transparent so I could see the temporary fixtures (e.g. collets, chuck, and stock) relative to the table.

My transparent fixture setup with 5C step chuck fixture, stock, and D20 model.

Or optionally, I can turn off the 5C collet and turn on a chuck instead.

At one point, I stopped and contemplated that I could have just bought any of two dozen variations of high-quality polyhedral dice and had them shipped here in less time and for much less effort than making them, but it was a good project and I rationalized it to a great opportunity to finally get 3+2 milling so many years after buying my Nikken table.

Fusion and 5-axis (3+2) Milling

I'm using Fusion 360 now and I'm in love with this product. Though I am still cutting my teeth on 3+2/5-axis machining, my opinion is that Fusion (its cam engine) is still new in the 5-axis world. Throughout the learning curve, I discover certain things about how Fusion deals with multi-axis machines that are either not yet implemented, or not in line with industry norms because their product is still evolving. These range from not being able to specify offsets for the axes themselves, to moving the tool (rather than the fixture) during CAM simulations.

Still, for beginners and hobbyists, and even for some veterans who just want to getter' done, Fusion 360 is an incredible tool for the price and beats other CAD/CAM packages hands-down.

Incidentally, I'd like to offer a special thanks to Alibre who after selling me a pro license, nickeled-and-dimed me every year that followed for maintenance fees that added little to no benefit to the product, then got taken over by GeoMagic who rebranded the product (distancing themselves from Alibre even more), then reclaimed their company as Alibre, and finally disabled the license server for my installation. Thank you, Alibre, for convincing me to abandon your product. You made it so easy to leave. Were it not for your greed, mismanagement and nonsense, I never would have discovered just how much better Fusion 360 is.

Until next time, keep spinning

Torin...

Comments