Metal Lens #2 and Fly Cutter Build

- Torin Walker

- Aug 18, 2018

- 5 min read

I figured the outcome from this experiment would be the same as the first one, but I was begging for an excuse to build a fly-cutter. So before I could start milling a concave surface into the other side of the metal block from part 1, I set out to build a tool that could give me a minimum 100mm diameter cut.

A fly cutter is a very simple single-point rotating cutter used to mill surfaces flat. While any end mill when passed back and forth over the same area will remove the same material, a fly cutter (with the proper diameter) can take the whole thing in one pass leaving a nice milled surface. I already have a 3" face cutter but wanted something larger. Something that would go up to maybe 6 ~ 8 inches.

So here is the other side of the lens you saw in the previous post. 4" diam, 4140 HT steel. I centered it on my 4-jaw in the tilting/rotary (TR) table and will set this at 2.5 degrees.

To cut this metal into a lens shape, I need to angle the table so that a cutter rotating in the XY plane scoops out the metal. As one rotates the table axis 360 degrees, the scooping cutter will carve out a concave surface.

The intersection of a 100mm circle (the cutter) with the workpiece at 2.5 degrees gives me the approximate 1000m radius of curvature I'm looking for. I calculated this in CAD, but ended up ballparking the cutting radius. Close enough. Here's a simple drawing to illustrate

* If you are exactly on center

But first, I need the cutter!

I looked at my existing tools, but all I have is a precision boring tool and those cheap boring bars that don't have enough clearance

So with a 1" collet, I thought I would mill myself a holder out of a 3" piece of 4140 HT

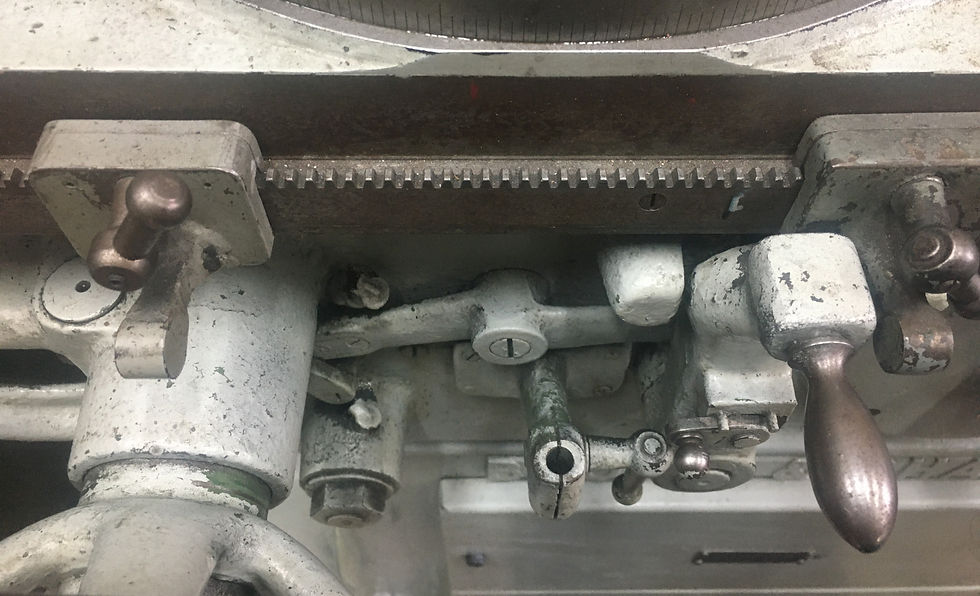

But then I remembered this weird tool I had lying around for ages. Don't know what it's original purpose was, but it's just collecting dust so I decided to re-purpose it. Was it someone else's stalled fly-cutter project?

I turned it down from 4.5 inches to 3.5". I wanted a large cutter, but didn't want a big gap between my 3" and this new one. It turned pretty nicely, so I'm guessing this is a prehard-steel as well by the way it produced chips and how it took on a shiny finish with heavy cuts, just like 4140.

So I remounted this platen into the 4-jaw and milled a 7.5 degree taper into the piece.

Nearly done. I was worried that I'd rip the flycutter body out from the tiny AEG low-profile 4-jaw, so I took 1/4 x 1/4 passes with a 5/8 endmill.

Using a smaller 7/16 endmill, I milled the slot for the HSS toolbit. Despite watching This Old Tony's Flycutter video and hearing his concerns about the placement of the slot, I still lost track in the details and put it on the wrong side. Thanks for jinxing me, Tony. Now I have to fly-cut in reverse for the positive angle approach he mentioned, though I think it's less critical than the positive rake normal to the plane of rotation, so whatever. Proof will be in the pudding.

I went in at ~ 1/8 per pass to 1/2" depth, stepped +X to clean up the wall, then stepped left until the slot matched my 1/2" HSS toolbit.

Once the second side was cleaned up, the toolbit slipped in perfectly with no gap at all.

Next is to mill the side for the set-screw clearance. I wanted enough meat so I could really crank down the screws.

Without taking it out of the TR table (one of the benefits of having such a table, which I paid a fortune for) is that I need only rotate the chuck 90 degrees and lean it over to start spotting and drilling the set-screw holes.

What you don't see here is the incredibly awkward setup. My TR table is on the left side with the cables protruding from the front, meaning I must look behind my machine to see what I'm doing. PITA! I'll swap my TR table and the Kurt vise one of these days...

I drilled three holes at 1" centers and picked up on the tapered surface with a 0.200 touch-off tool, then dialed back .350 (1/4" + 0.1) to hit center.

Naturally, I had all the wrong fasteners and taps, but finally found a super-sharp M6 Dormer tap that cut this steel like ... not butter, but more like carving a carrot. It has this certain crisp cutting feel that lets you know it's going well. I am perpetually paranoid about breaking off small taps. Want broken taps? Buy your taps from Canadian Tire/Harbor Freight. Want to slice through steel effortlessly? Get Dormer or Union Butterfield. Don't skimp on taps - especially the small ones.

Use plenty of oil and back out completely every so often to clear chips. I'll have to get myself some spiral taps one day, but it came out perfectly all the same.

And like a dolt, I forgot to take pictures of

hand-filing to break corners.

countersinking screw holes

grinding the HSS toolbit for 7-degree clearance front and bottom

marking the cutter body with a centerline so I can measure offset of the cutter

inserting the HSS toolbit and fastening with M6 socket-head screws (all I had on hand at the time)

But here's the first attempt. I centered the spindle and table axis, then stepped Y+ 50mm to put the cutter on center with the workpiece. If you go too little or too far, you get a nub in the center. This is where the results are identical to using a lathe. In the future, if I end up making metal lenses, I'll use the lathe instead. Easier. Much safer.

The first pass was with the workpiece at zero angle. I wanted to shave off the high spots before attempting a concave pass. Not much to see here except you might notice the lettering disappearing around the edges.

When I angled the workpiece and took a skim-pass, it cut initially then wore away the grind on the chinesium toolbit. I'm not even sure it's HSS.

So instead I put in an old right-hand brazed toolbit I was lucky enough to have lying around, but had to now spin the fly-cutter clockwise (looking down at the table.)

The first pass worked out very nicely. It left a little nub, so I brought Y back over center to get rid of it, then started cranking the C axis.

Dropping Z by another 0.01", I took a second pass that cleaned up the surface very nicely. Step over is too high because I was using the pendant to rotate the C-axis at 10 thou per pulse.

So this curve is much shallower because I had to extend the cutter to 150mm diameter to clear the cutter body, and the nub still isn't completely removed.

But hey, now I have a fly cutter! Not bad for a couple of hours of fun in the shop!

Until next time. Keep spinning!

Torin...

Comments